Metalenz, a startup founded by applied physicists from Harvard, is developing a lens system that is smaller but better performing than conventional smartphone lenses. The company is prepping to produce its innovative lenses not only for smartphones but for the automotive and healthcare industries as well. Smartphone camera lenses have come a long way, starting from tiny sensors with VGA resolutions to the more sophisticated 600-megapixel lenses now being developed.

The outcome of such developments result in smartphones with an increasing amount of heft after each iteration. As the technology of smartphones cameras evolve, so does the amount of space it occupies, leading to larger, more unsightly rear camera units that gradually protrude further into a bulky mess. However, new developments in camera lens technology are now pushing for camera modules that are more shrunken in form instead of ones that expand.

Metalenz says it has managed to achieve that by introducing a new type of flat lens that is “wafer-thin.” So-called "metalens" technology is capable of redirecting light “at will,” omitting the need for thick lenses that need to be stacked to be able to generate clearer images. The technology behind it is the brainchild of renowned applied physicist Federico Capasso and his team at the Harvard School of Engineering and Applied Sciences. The startup received $10 million in funding to manufacture products utilizing the technology for a wide range of applications including smartphone cameras, self-driving vehicles, drones, and satellites, along with potential uses in wearable optics such as smart lenses, virtual reality, and augmented reality.

Metalens Tech Benefits For Smartphone Cameras

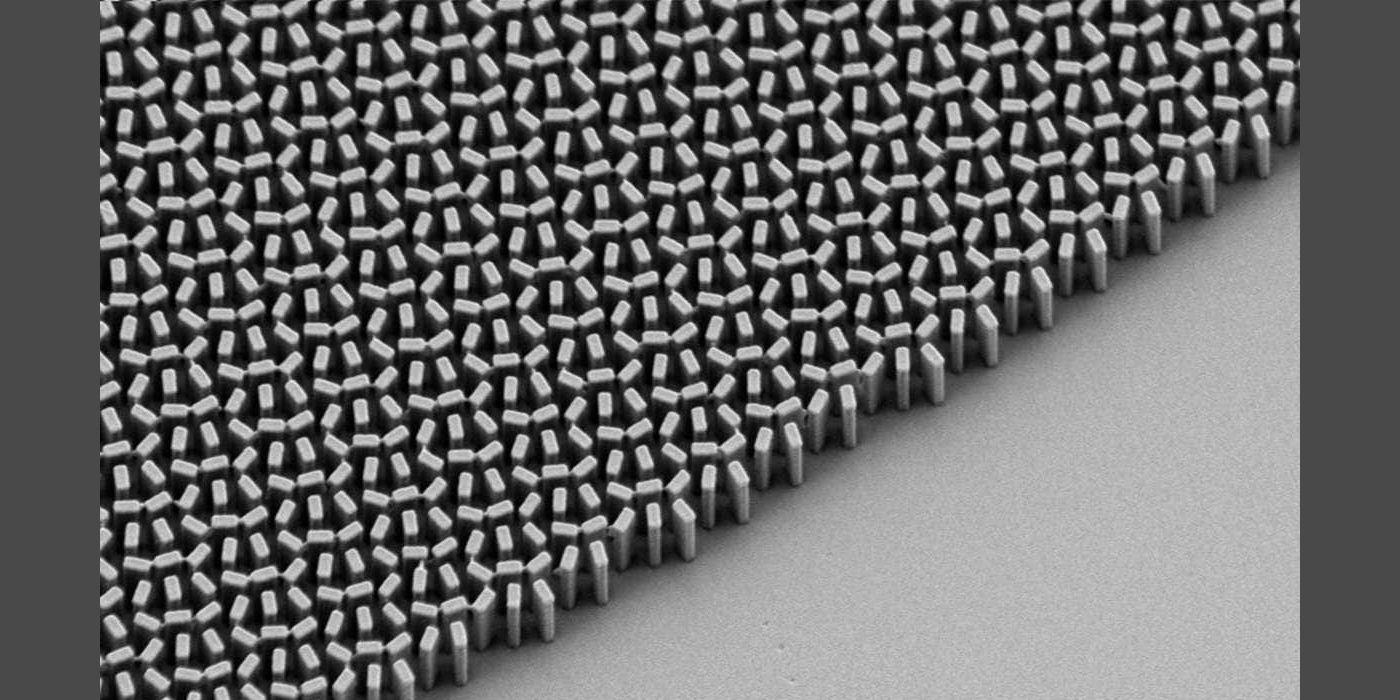

While smartphone manufacturers find ways to innovate camera modules, Metalenz aims to revolutionize them by decreasing both their scale and cost. Based on its case study, the team utilized a common material usually found in paint or sunscreen called titanium dioxide, to form a minuscule layer of nanostructures that make up the lens. Unlike traditional lenses that require expensive manufacturing costs, lengthy assembly periods, and meticulous quality control procedures to ensure optimal performance, meta-optics can be mass-produced in a single step and at a fraction of the cost. However, this won't just result in potentially cheaper smartphones, but ones with better camera capabilities as well, without the need for bigger apertures in lenses to achieve better image results.

Meta-optics are said to be capable of manipulating light on a level that conventional lenses are incapable of. Metalenz claims that a single meta-optic can outperform layers of refractive lenses. Other advantages that meta-optics bring to smartphones include better performance under sunlight, higher resolution, longer battery life, and improved facial recognition efficiency. It would be interesting to see how the technology can be applied to other camera concepts as a means to elevate the standards of smartphone cameras in the near future. If so, then perhaps the time of smartphones with bulky camera modules and unsightly punch-hole lens design will finally come to pass, making way to a new wave of sleeker, futuristic-looking handsets.