Tesla released a new killer video of a drone making a flythrough of its new Gigafactory in Berlin. There is one thing electric vehicle makers are focused on this year, scaling up production and meeting increased demands. The first quarter of 2022 has been rough for car brands in the all-electric business. They have been battling a surge in orders, inflation, and supply chain problems. The question on everyone's mind is, can they deliver?

The car industry was the first sector to embrace automation and robotics fully. All car brands today streamline production with robots explicitly built to build cars. However, Tesla has been known for pushing the limits on automation and robotics with artificial intelligence. Their goal has always been to operate the most advanced car plants in the world.

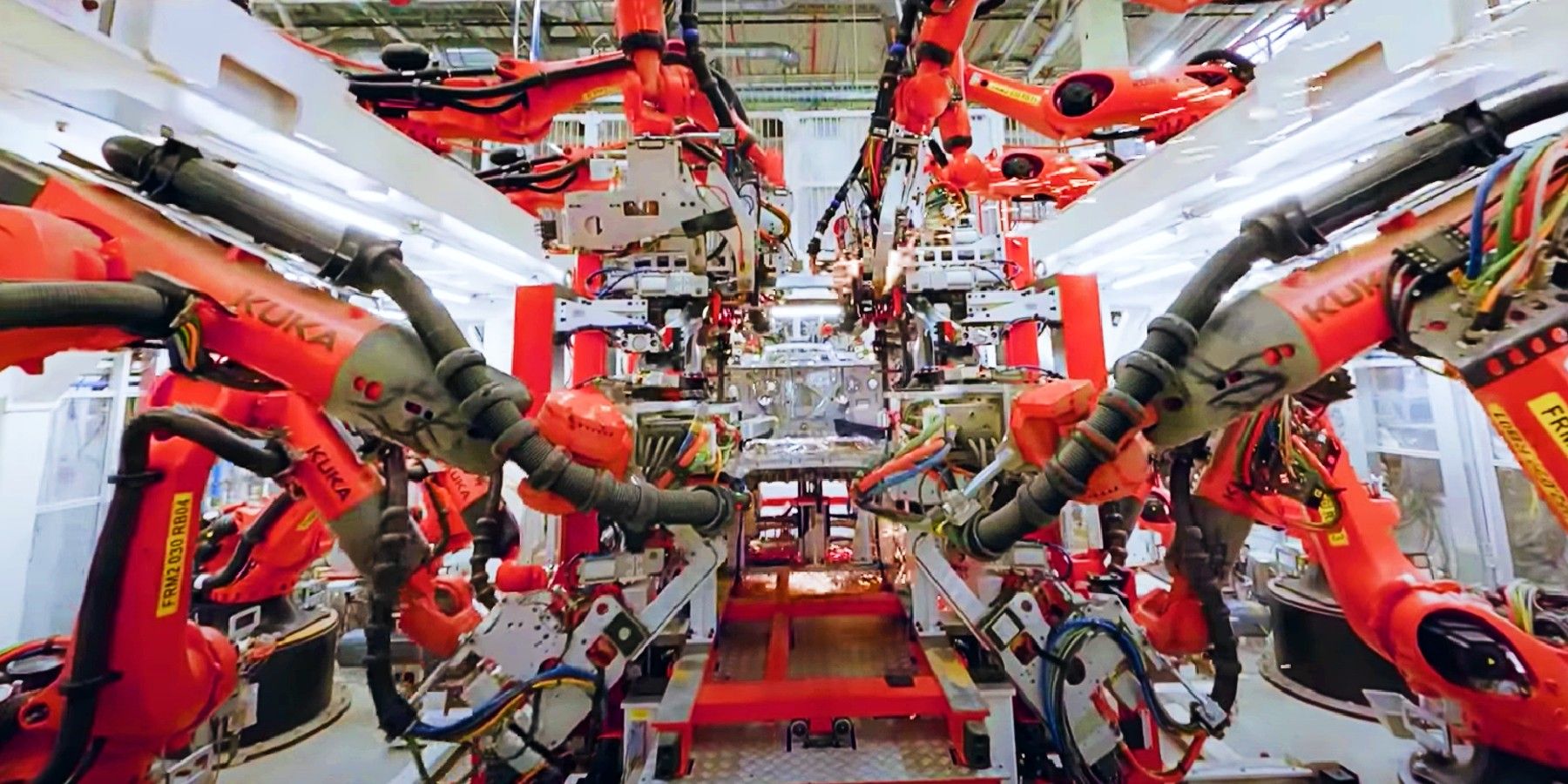

In a video, Tesla shows off the advanced high-tech operations of their new Berlin Gigafactory. The video was released on the same day the company announced they produced 305,000 vehicles and delivered 310,000 cars in the first quarter. The video seems to be how Tesla responds to those who question that the company will not be able to meet the surge in orders. Tesla's plant reveal sends out a clear message, they have gone all-in with automation, robotics and AI.

Mass Production To Feed The Global EV Appetite

Tesla's approach to car building is unique. Not only is its level of automation breathtaking, but the entire car is built from scratch in-house. Tesla says that its new Gigafactory will double its global production and is the most advanced, sustainable and efficient facility they have ever made. The plant will not only produce hundreds of thousands of Tesla cars every year, but it will also manufacture millions of battery cells.

Tesla has been working to apply AI to the supply chain and its plant for years. As reported in 2018 by Clean Technica, the term "automating intelligently" describes Tesla's robotic factory. Tesla robots are not just performing programmed tasks. Instead, they are linked to an AI that continually learns and figures out how to do things better and faster.

In Berlin, Tesla robots start by cutting and shaping steel and aluminum sheets. Then multi-arm robots weld together the chassis in seconds in an endless production line. Further down the line, a robotic arm lifts car after car as if they were weightless. From chassis to painting, robots do it all. A highly specialized human workforce monitors the army of robots. This is how Tesla is scaling, mass-producing cars in Berlin in what seems to be the most advanced EV car factory ever to operate.

Source: Tesla/Youtube, Tesla Press Release, Gigafactory Berlin, Clean Technica