The semiconductor shortage, which has affected the technology and automotive industries since 2020, is expected to continue through 2024 due to a lack of manufacturing equipment, according to Intel's CEO, Pat Gelsinger. The logistics disruptions incited by the COVID-19 pandemic in that year affected the total output, but other concerns have resulted in a dire situation. At one point, microchips were reserved for more traditional computers — now, they're present in everything from microwaves to cars. Even the largest companies are suffering from the problems. As a trillion-dollar corporation, Apple is facing bleak supply numbers. Recent reports suggest the problem won't be solved anytime soon.

Aside from purely logistical considerations, world events are impacting the production of microchips and worsening the situation. The Russo-Ukrainian conflict is expected to further strain the availability of chips since both countries are key exporters of critical components found inside modern processors. In addition, Russia is a significant harvester of neon gas — used to create microchips. Incidentally, the refinement of those gases takes place in Ukraine. As such, external conflicts are likely to affect the total output for both processes. The economic sanctions issued by the United States and its allies may also limit the production of neon gas and palladium, limiting the number of microchips that can be made per year.

Gelsinger, who is currently in his second year as Intel's chief executive, told CNBC that the company now expects the chip shortage to continue into 2024. Previous reports suggested that the supply and demand issues might be corrected as early as 2022 or 2o23, but those estimations have been extended. Though Intel and other companies are prepared to invest in the manufacturing centers necessary to increase output, similar disruptions have occurred in acquiring those tools.“That’s part of the reason that we believe the overall semiconductor shortage will now drift into 2024, from our earlier estimates in 2023," Gelsinger said on CNBC's TechCheck. "Just because the shortages have now hit equipment and some of those factory ramps will be more challenged.”

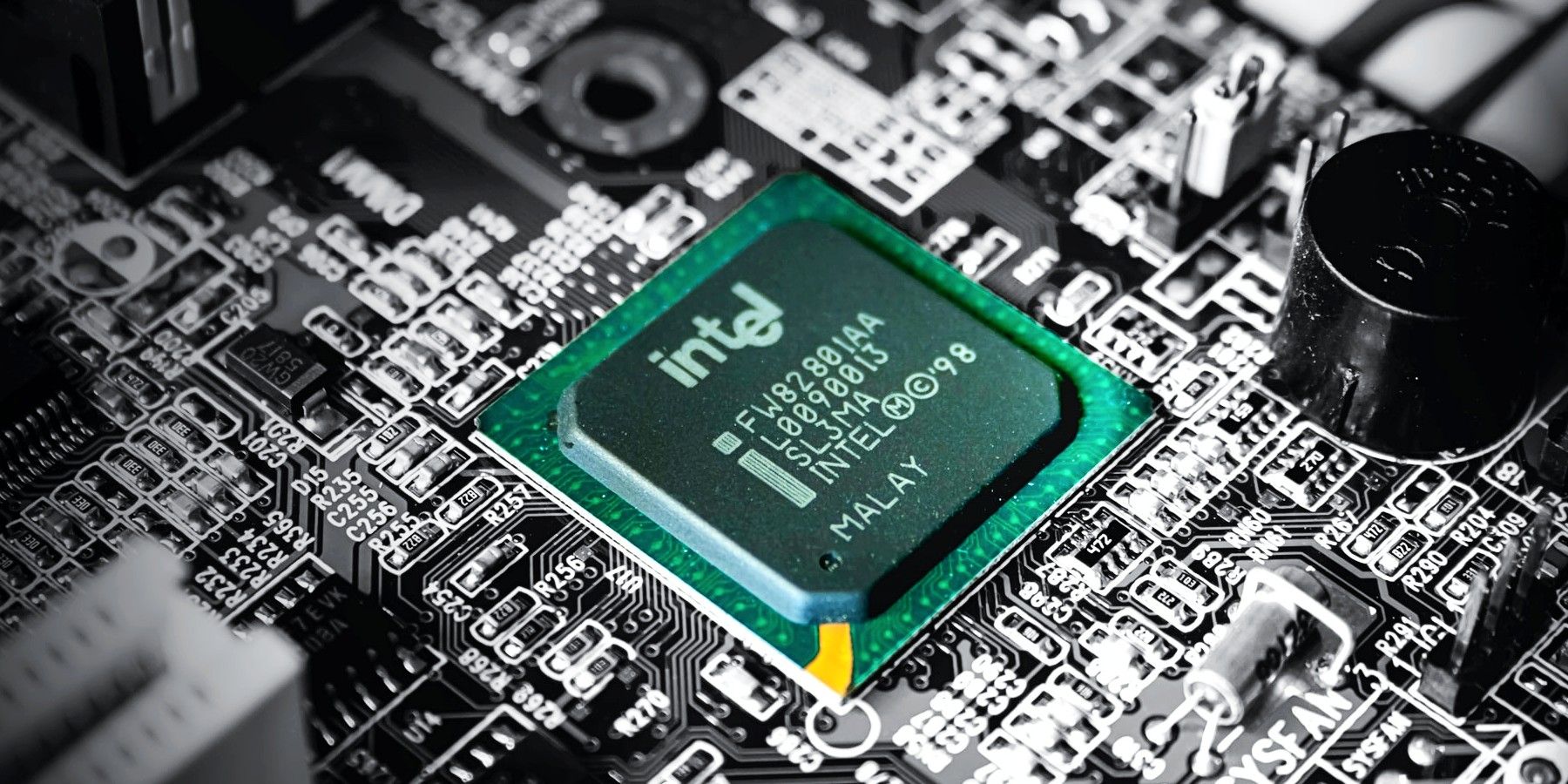

Intel Investing In The Production Of Microchips

Intel is investing in new production sites and methods despite the supply chain issues now affecting the manufacturing processes of microchips. The company has made a $3 billion investment in its D1X semiconductor development facility in Oregon, which is the primary development site of Intel's fabrication processes. Historically, these improvements in manufacturing processes become significant every two years, as the chips can be produced on a smaller level. Though the shortage is expected to continue, Intel was able to successfully open the new facility in April 2022, according to the company. The location will be one of the new and upgraded locations for the company's engineers to make improvements on their line of consumer and professional processors.

Just as the company has demonstrated a willingness to invest in the manufacturing tools necessary to improve their chips, they've also invested in the engineers that will design them. For example, Intel poached Jeff Wilcox — who served as Apple's chief systems architect and developed the company's system-on-a-chip (SoC) processors for more than a decade — earlier this year. He designed the Apple Silicon chips that bested Intel and eventually became the primary processors throughout Apple's lineup. So while Intel expects the chip shortage to continue into 2024, its eagerness to invest in the people and facilities that will develop new processors is sure to grow the company.